What is a Destratification Fan?

What is a Destratification Fan?

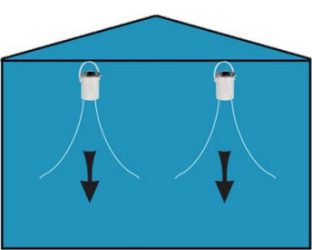

A destratification fan is a ventilation device, typically suspended from the ceiling of a commercial or industrial building. Two main purposes of this fan are to achieve energy savings and provide a more comfortable environment for occupants in a building. This is done by circulating air from the ceiling to floor level, reducing the temperature difference between the highest and lowest points and creating an even temperature distribution.

Stratification

It is common knowledge that hot air rises due to the excitation of molecules. An increase in energy causes the air molecules to collide and spread out; the hot air is thereby less dense and begins to rise. In a large warehouse, this hot air can be trapped at the ceiling, providing little warmth to the occupants at floor level. This issue is exacerbated in buildings with high ceilings.

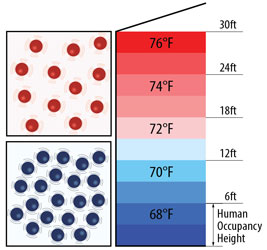

The free space in a building normally contains distinct thermal air layers, called strata. Each stratum has a different average temperature, forming a temperature gradient from the floor to the ceiling. For every 3-foot increment of height in a building, the temperature is assumed to increase by 1 F. Considering that an average industrial building is approximately 30 feet high, this would result in a significant 10 F average temperature difference from floor to ceiling.

The free space in a building normally contains distinct thermal air layers, called strata. Each stratum has a different average temperature, forming a temperature gradient from the floor to the ceiling. For every 3-foot increment of height in a building, the temperature is assumed to increase by 1 F. Considering that an average industrial building is approximately 30 feet high, this would result in a significant 10 F average temperature difference from floor to ceiling.

Building Temperature

For occupant comfort, the temperature needs controlled for the first 6 feet from the floor. Yet, often times the heat required for occupant comfort will rise toward the ceiling and the occupied space will continue to call for heat. The occupants are not comfortable and energy is being wasted.

This rising heat also contributes to the acceleration of heat loss through the building roof. The greater the difference between the outdoor air and indoor air near the ceiling, the greater the heat loss through the roof.

This rising heat also contributes to the acceleration of heat loss through the building roof. The greater the difference between the outdoor air and indoor air near the ceiling, the greater the heat loss through the roof.

In summertime, the impact of stratification may be also evident on the floor of other industrial spaces, such as machine shops. For anyone who has found themselves surrounded by rows of large machinery during peak hours of operations, the heat generated from these machines can be unbearable. Since the higher strata layers resist a change in temperature, much of the heat on the shop floor is retained, providing little relief to the occupants.

Condensation

Not all water puddles on the floor of industrial and commercial buildings are caused by leaks in the roof. If water is dripping from a ceiling, before hiring a contractor to inspect the roof, consider the possibility that condensation may be the cause. Condensation is formed when the temperature of a surface is at or below the dew point of the surrounding atmosphere. A common example is the buildup of water droplets on a cold water bottle during a hot summer’s day.

Not all water puddles on the floor of industrial and commercial buildings are caused by leaks in the roof. If water is dripping from a ceiling, before hiring a contractor to inspect the roof, consider the possibility that condensation may be the cause. Condensation is formed when the temperature of a surface is at or below the dew point of the surrounding atmosphere. A common example is the buildup of water droplets on a cold water bottle during a hot summer’s day.

In winter, condensation in a warehouse can be caused by a cold ceiling and warm rising air. As the roof conducts the cold outdoor air, it comes in contact with the warm indoor air and condensation forms on the ceiling. The condensation builds up and begins to drip on the floor, resulting in a slipping hazard for the occupants and potential damage to equipment and product. This effect is inherently evident in buildings with poor insulation.

Destratification will mitigate condensation buildup by circulating the warm and humid air trapped near the ceiling toward the ground floor and reducing the relative humidity and temperature gradient at the top.

Benefits of Destratification

A destratification fan’s value can be seen during the heating season. The airflow generated by a destratification fan provides the force necessary to circulate airflow through the strata, while distributing heat through convection. Destratification effectively moves hot air away from the roof and toward the occupied floor of the controlled area.

The benefits of destratification extend to building managers and the environment. A destratification fan can eliminate unnecessary strain on a heating system. Heating savings of up to 50% may be achieved through the proper installation of destratification fans. The environment benefits from the reduced levels of energy consumption, exhaustion of natural resources and pollutants introduced into the atmosphere.

It is common now for buildings to be required to conform to environmental ‘green’ codes. Measures toward achieving compliance can sometimes come down to the simple addition of destratification fans.

Technical Concepts

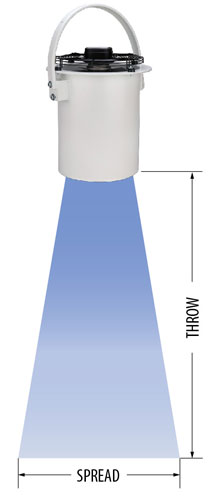

There are two key terms to understand when considering destratification: Fan Throw and Fan Spread.

There are two key terms to understand when considering destratification: Fan Throw and Fan Spread.

Fan Throw is the distance air will travel. For destratification fans, this is the distance from the fan outlet to the ground floor. The ideal Fan Throw will allow the occupants to feel the comforting effect of the fan, but not to the point that it will be bothersome and promote the circulation of dust. This is done by choosing a fan that will provide an appropriate terminal velocity. Common terminal velocities used in the industry are 50, 100 and 150 feet per minute (fpm). Depending on the application, destratification fan specifications may indicate the Fan Throw at one or all three terminal velocities listed above.

Fan Spread measures the amount of space one destratification fan unit will cover at a certain Fan Throw (distance) from the fan inlet. This is a key factor to note when determining fan location(s).

Destratification fans should be installed in locations that target areas of high traffic and minimize any space outside of the fans’ spread. It is also important to ensure there is minimal obstruction of airflow caused by equipment and inventory storage. This can limit a fan’s spread and prevent airflow from reaching ground level. As a basic rule for an even airflow distribution, each fan should be installed half a Fan Spread diameter away from walls, and a full Fan Spread diameter away from neighboring fans.

Types of Destratification Fans

Two common types of destratification fans are the paddle blade fan and the round cased fan.

Paddle blade fans rely on large impeller blades to move high volumes of air at relatively low rotational speeds. Typically, these fans are seen as the energy efficient option, requiring smaller horsepower motors to move an equivalent amount of air, when compared to standard speed fans. Occasionally, the height of a building or severe stratification may render these fans ineffective. An alternate method may be to use higher velocity round cased fans.

Round cased fans, such as Continental Fan’s DSF models, are effective when space and exposure are a concern. There are a limited number of places on a ceiling that a fan can be installed due to obstructions such as lighting, ventilation and rafter positioning. The compact footprint of round cased fans immensely expedites the installation process. A rotating mounting bracket can allow the fan to be angled, directing the airflow to a desired location. In situations such as athletic facilities, where there exists the possibility of objects coming into contact with the fans, critical components such as the impeller and motor are protected by the fan housing and guards.

Accessories

Guards

Guards should be considered to prevent the possibility of foreign objects coming into contact with the fan blades or motor. Motor side guards are included with Continental Fan’s DSF Fans.

Safety Hanging Cable

A safety cable is an important accessory to have, particularly with round cased fans. The safety cable acts as a backup to the primary cable and mounting bracket in the event of failure. Gripple Hanging/Safety Cables are included with Continental Fan’s DSF fans.

A safety cable is an important accessory to have, particularly with round cased fans. The safety cable acts as a backup to the primary cable and mounting bracket in the event of failure. Gripple Hanging/Safety Cables are included with Continental Fan’s DSF fans.

Speed Control

A speed controller can be a useful tool to adjust the performance of a fan and account for changing requirements. Depending on seasonal changes in weather and temperature, airflow may need to be adjusted accordingly. Fan speed can also be lowered during off-peak operating hours, when the number of occupants is reduced, resulting in energy and cost savings. A speed controller, such as Continental Fan’s SCN or VSC, is a great addition to any building management system.

- Closed Loop Control

This feature may be available on some speed controllers, and can be combined with temperature and humidity sensors to vary the speed of the fan as required. - Multiple Fan Control

This feature may be available with certain fan models, allowing multiple destratification fans to be controlled using a single speed controller. This can reduce system complexity, while saving time, effort and money.

Determining Size and Quantity

Destratification fans are likely to have the ideal height range specified for each individual model. Knowing the height of a building and a fan’s recommended height range are key factors when determining which fan size and the number of fans to use.

Destratification fans are likely to have the ideal height range specified for each individual model. Knowing the height of a building and a fan’s recommended height range are key factors when determining which fan size and the number of fans to use.

The number of units required for the destratification of a building can be estimated by considering the entire volume of the controlled area. Note that this approximation does not take into consideration the coverage of each individual fan spread. The formula below addresses the minimum number of fans of a certain capacity (cfm) required for the destratification of the total room volume, at a rate of one air change per hour;

Minimum number of Units = Length (ft) x Height (ft) x Width (ft) / [ cfm x 60 ]

The result can then be rounded up or down to the nearest whole number, based on which whole number of fans will better service the layout of the building. This is further illustrated in the example below.

Example

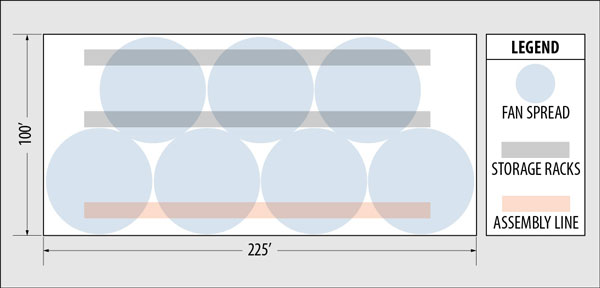

The building manager of a packaging warehouse is looking to install some destratification fans after reading about the possibility to increase energy savings and occupant comfort. The warehouse is 100 feet long by 225 feet wide, with a 20-foot-high ceiling. After researching destratification fans, the manager finds three round-cased Continental Fan models to choose from:

| Fan Model | DSF250 | DSF300 | DSF350 |

| Maximum Airflow (cfm) | 420 | 1055 | 1460 |

| Ceiling Height (ft) | 15-19 | 20-24 | 25+ |

Considering the ceiling height ranges indicated in the table, the manager chooses to use a DSF300 Fan for his warehouse with a 20-foot-high ceiling.

The recommended number of destratification fans is determined using the formula below:

| Number of Units | = Length (ft) x Width (ft) x Height (ft) / [ cfm x 60 ] |

| = 100 x 225 x 20 / [ 1055 x 60 ] | |

| = 7.10 | |

| = 7 units |

The following destratification floor plan is developed for this scenario:

The seven DSF300 fans are positioned by taking into consideration fan spread and occupancy. Four fans are placed near the assembly line, which can be considered an area of high occupancy, while the remaining three fans cover the less frequently occupied storage racks. These three fans are also not placed directly over top of the storage racks, in order to minimize airflow interference.

A Continental Fan SCN speed controller is used to turn down the speed of all seven fans during off-peak hours of operation.

All the required information has been gathered in order to purchase and install a successful destratification system, which can help to improve occupant comfort while reducing the rising costs associated with the heating and cooling of the packaging warehouse.

Download a PDF copy of our Destratification Fan Application Guide today!