For a quick refresher on fan fundamentals, download a PDF copy of our Fan Basics: What is a Fan?; Fan Impeller; Fan Terminology; Fan Laws; Fan Ratings; Selecting a Fan; Airflow Rate; Static Pressure; Fan Curves; Which Fan to Choose?______________________________________________________________________________________

FAN BASICS: WHAT IS A FAN?

A fan is a power-driven machine used to move a volume of gas. In other words, a fan is an air moving device. In its simplest form, a fan comprises a motor, a fan housing and a rotating impeller. A fan’s impeller design, its rotational speed, and the power supplied by its motor dictate the volume of air that the fan is capable of moving and the amount of pressure it is able to develop in helping to overcome any resistance to airflow that may exist.

In broad terms, fans can be described as being used for either general ventilation or process ventilation. General ventilation fans tend to be relatively low pressure devices. They include wall exhausters, roof ventilators, domestic bathroom fans and even common desk fans. Process ventilators are typically higher pressure fans and often involve some form of channeled airflow.

Fan designs vary according to application. They include cooling fans for small computers, large electronic cabinets, medical appliances, or airport screening devices. Industrial applications include powerful blowers used to ventilate underground mines, blast furnaces, rail cars and locomotive engines.

______________________________________________________________________________________

FAN IMPELLER

A fan impeller is the rotating portion of the fan, designed to increase the energy level of the gas stream it is operating in. In simple terms, it is the part of the fan that creates the actual flow.

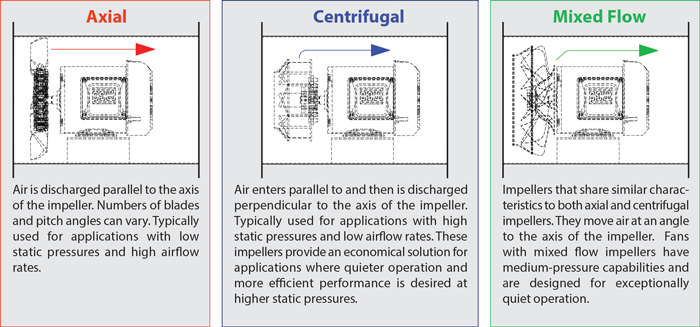

There are several different types of fan impellers, and they are available in a wide variety of designs and sizes. Selecting the correct impeller for an application is very important because each provides unique and different advantages.

The three most common types of impellers are:

______________________________________________________________________________________

FAN TERMINOLOGY

Air Change Rate (min/AC)

The amount of time required for the air in a room to be completely exchanged. Dividing a room’s volume (cubic feet) by the desired rate of air change (minutes) will determine the required airflow rate (cfm) and resultant fan capacity.

Airflow Rate (cfm)

The volume of air that is moved by a fan within a specified period of time, expressed as cubic feet per minute. An airflow rate is required before a fan can be selected.

Brake Horsepower (BHP)

The actual power absorbed by a fan at its operating point. BHP depends on many factors, including fan speed and a system’s static pressure and airflow rate.

Fan Curve

The graphic presentation of a fan’s performance characteristics, showing airflow, static pressure and brake horsepower. Sound levels, efficiency, and other parameters may also be displayed. Unstable operating regions (stall, or left of peak) are typically not shown.

Fan System

The series of components such as ductwork, dampers, filters, nozzles, diffusers, etc., which are connected to a fan and guide the flow of air or gas. The fan is the component in the system that provides energy to the air stream to overcome the resistance to flow of the other components.

Operating Point

The point of rating for a specific fan that corresponds to the intersection of its performance curve with the system curve in which it is operating.

Outlet Velocity (OV = cfm/outlet area (sq. ft.))

The speed at which air is discharged from a fan outlet (fpm).

Peak Power

Unlike brake horsepower (BHP), peak power represents a fan’s highest possible absorbed power value that may be encountered should operating conditions change. Peak power should be considered when choosing a suitable motor.

Pressure

The measure of force generated by a fan over a unit of area. It is typically measured in inches of water gauge (in. wg). There are three different types of pressure that may be considered in a fan system: Static Pressure, Velocity Pressure and Total Pressure.

Static Pressure (SP)

A component of the pressure developed by a fan, which does not account for the effect of air or gas movement.

Velocity Pressure (VP)

A component of the pressure of a fluid, which only exists if the fluid is moving. For a fan, it is based on the average air velocity at the fan outlet. As the velocity of the airflow increases, the velocity pressure increases.

Total Pressure (TP = SP + VP)

The total pressure developed by a fan is the sum of its static pressure and its velocity pressure.

Sound Power Level

The acoustic energy emitted by a sound source. It can be expressed in watts or in decibels.

Sound Pressure Level

The acoustic pressure at a point in space where a microphone or listener’s ear is situated. It can be expressed in units of pressure or in decibels.

System Curve

A graphic representation of the relationship between the volumetric flow rate through a fan system, and the resistance to flow developed within that system.

Tip Speed (TS = fan circumference (ft) x rpm)

The peripheral speed (fpm) of the tip of an impeller, at any given rotational speed.

______________________________________________________________________________________

FAN LAWS

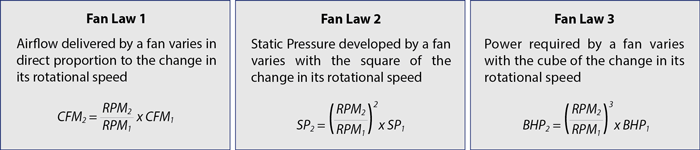

Fan Laws are used to accurately predict the performance of a fan at speeds and densities other than those presented in standard rating tables. For simplicity, we will confine our discussion to the basic Fan Laws – those dealing with speed variation.

Example:

A given fan is operating in a fixed system with constant density:

CFM1 = 10,000 cfm

SP1 = 1.50 in. wg

BHP1 = 5.00 BHP

RPM1 = 1,000 rpm

25% more air is desired. By using and rearranging the Fan Laws, we can calculate:

CFM2 = 12,500 cfm (1.25)¹ increase

SP2 = 2.34 in. wg (1.25)² increase

BHP2 = 9.77 BHP (1.25)³ increase

RPM2 = 1,250 rpm (1.25)¹ increase

In order to obtain 12,500 cfm using the original fan, the speed must be increased from 1,000 to 1,250 rpm and the motor must be changed from 5 to 10 hp. This may be not be possible, depending on the fan design and its construction. Increasing airflow in a fixed system is not as simple as it may first appear!

______________________________________________________________________________________

FAN RATINGS

It is not practical to test a fan at every speed at which it may be applied. Nor is it possible to simulate every density that may be encountered in operation. However, by using the ‘Fan Laws’, it is possible to predict, with good accuracy, the performance of a fan at speeds and densities other than those of the original rating test.

Similarly, it is possible to predict the performance of a complete series of geometrically similar fans based on the results of tests on smaller fans in the series. Test results, along with extrapolated values, are commonly presented in Fan Tables, or displayed as Fan Curves. By analyzing fan performance curves (or tables), a fan model can usually be found to deliver a specific airflow rate and static pressure.

______________________________________________________________________________________

SELECTING A FAN

Each fan system has unique requirements that can normally be satisfied from a wide selection of fan types, with differing arrangements and construction. Fan selection is usually a matter of choosing the best type and size from among those available.

Prior to selecting a fan type for a ventilation system, two fundamental requirements must be known or need to be determined: airflow rate and static pressure.

______________________________________________________________________________________

AIRFLOW RATE

Airflow requirements for process ventilation can be very specific and may involve detailed calculations.

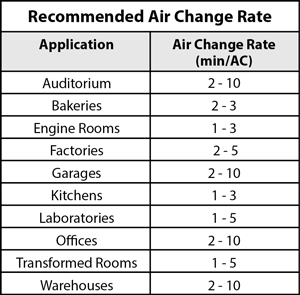

For general ventilation applications, the requisite airflow can usually be established based on the volume of air within a room, and the air change rate needed within it. Recommended air change rates for a variety of applications can be found in the Chart below:

The airflow rate and resultant fan capacity can be determined by dividing the room’s volume (cubic feet) by the desired rate of air change, as shown below:

______________________________________________________________________________________

STATIC PRESSURE

The static pressure within a fan system must be established before a fan selection can be made. Determining the static pressure in a system can be a complex matter. All items that may contribute to the resistance of air flow need to be considered, including inlet and outlet conditions, and friction losses from ductwork, elbows, dampers, screens, weather hoods and other appurtenances.

______________________________________________________________________________________

FAN CURVES

Having reliable technical information simplifies the task of choosing the correct fan for an application. Fan curves provide an accurate and graphical portrayal of a fan’s performance characteristics. Basic fan curves show airflow versus static pressure. Supplementary curves are often presented that display absorbed power, sound characteristics, a system curve and other useful information.

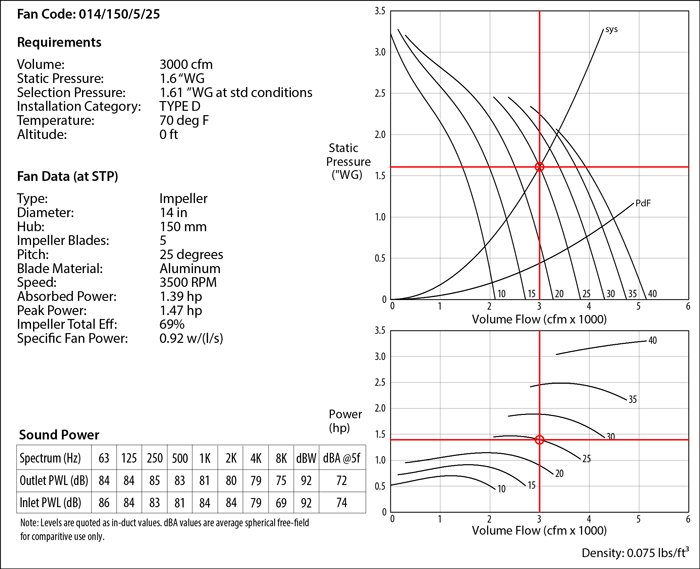

The following example illustrates a simple axial fan selection:

An industrial building needs to be ventilated. The fan system comprises an inlet hood, screen, filter, and a length of duct with discharge grille. Known parameters are:

• Airflow Required: 3,000 cfm

• Duct Diameter: 14”

• Static Pressure: 1.6 in. wg

This data is input to a specialized fan selection program that makes appropriate calculations and provides a range of results for different fan sizes that satisfy the input conditions. The results differ not only on fan diameters, but also on other parameters such as efficiency, speed, brake horsepower, and operating point on the fan curve. From the large number of available fan solutions, experience leads us to select a 14” diameter axial fan, which also happens to match the duct size. It has a factory set adjustable pitch impeller. Its fan performance data is shown below.

The numbered curves in the chart represent available blade pitch angles. For this fan, the impeller should be pitched at 25°.

A System Curve (sys), corresponding to the specified system, passes through the Operating Point. According to the Fan Laws, pressure varies with the square of the airflow rate, and therefore the system curve appears as a parabola. Also shown is a Velocity Pressure curve (PdF), from which the Total Pressure in the system can be determined.

Additional information pertaining to the impeller type, number of blades, material, operating speed and conditions, absorbed and peak power, efficiency, and sound characteristics is provided.

Sound Power is presented in eight octave bands. This useful information is important if it necessary to install a silencer or design an attenuation system for the fan system. The last column in the table shows the calculated Sound Pressure level in dB(A) at a pre-determine distance.

______________________________________________________________________________________

WHICH FAN TO CHOOSE?

Once airflow rate and static pressure for a given fan system have been established, the question of which fan type to use can be addressed. In most fan applications, it is neither necessary nor desirable to design a completely new fan for the specific job requirements. Many standard fan designs are readily available to satisfy most system requirements.

A fan specification should provide a fan manufacturer with all the pertinent information regarding performance, service, evaluation, arrangement, etc. so that the best selection can be made. The number of fans and their aerodynamic type should be specified only after comparing the various possibilities. Distinct fan designs and models have discrete attributes that can benefit specific applications. These include type of impeller, drive method, fan size and sound characteristics.

Selecting the correct impeller to use is very important, as it affects the efficiency and overall performance of a ventilation system. In general ventilation applications with high airflow requirements and low static pressure, axial fans are predominantly chosen. Process ventilation systems with typically higher static pressure and lower airflow requirements normally use centrifugal fans to satisfy most applications. Mixed flow fans have their own unique features and benefits, and are often used in low noise applications or where the risk of ‘stalling’ cannot be tolerated.

Direct drive is a popular drive method because fans tend to be more economical, operate efficiently, require little or no maintenance, and can be easily speed controlled by a variety of different methods. Belt drive fans are also commonly used, and are essential in certain applications such as hazardous locations that require the motor to be located outside of the airstream.

Fan size is an important consideration when deciding on which fan to use. A smaller, high speed fan may deliver the performance required for a ventilation system, but at the risk of high noise and power consumption. A larger fan may run slower, absorb less power and be quieter, but it could be more costly to purchase and install, and may not fit in the system. An alternative may be to use multiple smaller fans running in parallel to achieve a similar performance.

Finally, sound characteristics play an important consideration in choosing the correct fan for an application. Different fan types, sizes and operating speeds produce differing noise profiles, some of which are more difficult to attenuate than others.

Deciding on the correct fan to use can be a daunting task with many variables to consider, but there is always a ‘best choice’ available when all factors are taken into account.

______________________________________________________________________________________

Download a PDF copy of this blog post today!